Simple. Reliable. Remarkable.

Case Erectors

INSITE case erectors are designed to deliver one outcome exceptionally well: form and seal consistently square cases with minimal downtime or operator effort. While case erecting seems simple, anyone who has battled skewed cases, jams or tricky blanks knows it’s a task that requires thoughtful engineering. That’s why we build machines that give you fast setup, reliable performance and smooth, frustration-free operation.

Designed for Reliable, Real-World Performance

INSITE case erectors are engineered to deliver more than a bottom-sealed case. They’re built to be:

- Consistently accurate – producing reliably square cases

- Easy for operators – simple changeovers and intuitive controls

- Accessible – ergonomic magazine loading and open-frame structure for easy access

- Highly efficient – consistent performance with minimal downtime

- Dependable – robust design with fewer mechanical parts results in less maintenance

- Plant-floor friendly inline layout

- Safe – ANSI/PMMI B155.1, ISO 13849 Category 3 (standard for glue machines), and UL certified

Key Features of INSITE’s Case Erector

INSITE’s simple mechanical architecture and robust components reduce maintenance costs and contribute to long-term value.

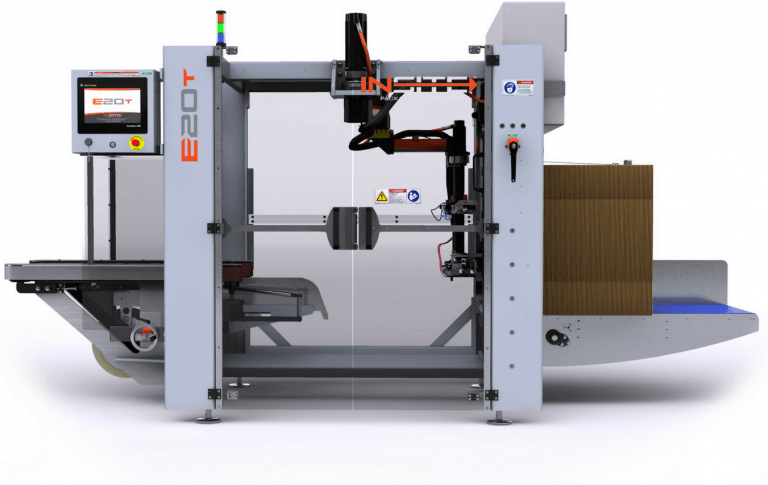

Automated Path Generation

INSITE’s proprietary motion control software generates robot paths using only the case’s outside dimensions. This reduces mechanical complexity and replaces many traditional components with a single SCARA robot.

Positive Case Opening

The opposing-cup design reliably opens cases – even when dealing with glue overspray or imperfect blanks – reducing stoppages and manual intervention.

Robotic Pick & Pass

Through utilization of our SCARA robot controlled by Rockwell Automation, INSITE removes many of the parts that typically require adjustment, lubrication or replacement. The result: quieter operation, fewer wear points and easier maintenance.

Operator-Focused Safety & Ergonomics

Safety is a top priority with features like easy-to-load magazine infeed, accessible changeover points, open-frame visibility for easier maintenance access, certifications such as ANSI/PMMI B155.1, ISO 13849 Category 3 (standard on glue machines), and UL.

Active Case Squaring

Photo eyes detect skewed cases and automatically correct them using independently driven side belts, resulting in consistently square, stable cases.

Durable & Sanitary Frame

Constructed from heavy-duty tube-and-plate steel, the frame resists wear, supports long equipment life and incorporates hygienic design principles.

Options

Most features that other manufacturers upcharge for are standard on INSITE machines. Additional options allow you to tailor the system to your operation.

Included as Standard

- Left- or right-hand orientation (determined by your case hand and your lines direction of travel)

- UL-listed electrical components

- Category 3 safety circuits (glue machines; optional on tape)

- Allen Bradley® PanelView Plus 7 HMI (12” user interface)

- Hygienic, accessible machine design

- Electronic case squaring

- Lubed-for-life gearboxes

- HMI-based recipe generation (create & store up to 32 recipes)

Available Options/Customizations

- Smart discharge control (senses downstream queue and adjusts speed to average line speed)

- Low tape/magazine alerts with stack light

- 6-foot magazine

- Spare parts kit

- Dust cover

- 3” tape head

- Large case and small case kits (to expand size range)

- Flap detection

- Autofill glue system

- Upgraded magazine follower

- Remote access EWON

- Alternate discharge height

- Additional e-stops

Specifications

If you’re looking for information that’s not listed here, please contact us.

| E20T | E20G | E20GT | E30T | E30G | E30GT | |

|---|---|---|---|---|---|---|

| Max. Speed (cpm) | 20 | 20 | 20 | 30 | 30 | 30 |

| Min. Case Size | 9” (L) x 5.5” (W) x 4” (H) (L+W must be ≥ 14.5”) | |||||

| Max. Case Size | 20” (L) x 16” (W) x 16” (H) (L+W must be ≤ 33”) | |||||

| Min. Case Size with Options | 7” (L) x 4.5” (W) | |||||

| Max. Case Size with Options | 24” (L) x 18” (W) x 20” (H) (L+W must be ≤ 40”) *Rates may be limited for large cases | |||||

| Min. Flap Length | 2.5” | |||||

| Max. Flap Length | 8" | |||||

| Case Types | Regular Slotted Cases (RSC), Half-Slotted Containers (HSC), Display Trays | |||||

| Magazine Length | 6' (72") | 4' (48") | ||||

| Magazine Capacity | 4’ (48”) ~130 cases, minimum ~6.5 min. run time Optional upgrade: 6’ (72”) ~190 cases, minimum ~6.5 min. run time | |||||

| Machine Footprint | 12.90' x 4.66' | 15.15' x 4.66' | 15.15' x 4.66' | 14.90' x 4.66' | 17.15' x 4.66' | 17.15' x 4.66' |

| Magazine Height | 18" to 26" | 1' 7" x 2' 1" | ||||

| Discharge Height | 27” +/- 1.5” (other options available) | |||||

| Frame to Floor Clearance | 3” to corner posts; 5” to center beam (+/- 1.5”) | |||||

| Frame | Tube and plate steel | |||||

| Cleaning - Structure | All-purpose, spray-on cleaner, 5-10 pH (non-electrical only) | |||||

| Finish | Powder coat | |||||

| Environment | Machine is intended to operate in dry, non-wash down, low-humidity environments | |||||

| Max. Ambient Temp. | 100° F | |||||

| Min. Ambient Temp. | 35° F | |||||

| Max. Humidity | 75% | |||||

| Changeover Points | 11 | 12 | 15 | 11 | 12 | 15 |

| Changeover Types | Tool-less | |||||

| Changeover Time (approx) | ~ 2.5 to 5 minutes | |||||

| Tape Width | 2" or 3" | N/A | 2" or 3" | 2" or 3" | N/A | 2" or 3" |

| Glue System | N/A | Nordson Flex | Nordson Flex | N/A | Nordson Flex | Nordson Flex |

| Vacuum System | Venturi-style | |||||

| Guarding | Lexan doors with locking switches | |||||

| Cleaning - Lexan | Clean with a soft, damp cloth. Abrasive pads should not be used. | |||||

| Lubrication | Non-food grade, lifetime lubrication | |||||

| NEMA Rating | 12 | |||||

| Electrical Components | Allen Bradley, Kinetix Servos, Powerflex VFDs | |||||

| Power Requirements | 480V 3Ø / 60 HZ | |||||

| Electrical Drops | 1 | 2 | 2 | 1 | 2 | 2 |

| Main Electrical Drop | 30 AMP rate disconnect; fused for 15 AMP | |||||

| Glue Electrical Drop | N/A | 30 AMP; fused @ 15 AMP | 30 AMP; fused @ 15 AMP | N/A | 30 AMP; fused @ 15 AMP | 30 AMP; fused @ 15 AMP |

| Est. AMP Loads | 12 | 14 | 14 | 12 | 14 | 14 |

| Air | 5.3 SCFM @ 70 psi | 5.3 SCFM @ 70 psi | 5.3 SCFM @ 70 psi | 6 SCFM @ 70 psi | 6 SCFM @ 70 psi | 6 SCFM @ 70 psi |

| Machine Efficiency | Case and/or product samples are required to validate size range and guarantee speed rates |

Innovation Built In

INSITE case erectors have been reimagined and redesigned from the ground up—untethered by old technologies and legacy mechanisms.

- Smooth robotic motion powered by proprietary software

- Fewer parts than traditional erectors (40-60% less than competitive erectors), reducing maintenance

- Fast, recipe-driven changeovers with fewer change points and the ability to run a new case size in just 2-5 minutes

- Significantly quieter operation enabled by simplified operation and the clean, quiet and smooth motion of our SCARA robot

- Simplified machine ownership with dependable performance from the first run

Progress With Purpose

INSITE exists to make your packaging operations stronger, more efficient and easier to manage. Every feature, every component and every design choice is made with your operators, your uptime goals and your long-term ROI in mind.

Resources

Explore layouts and floorplans, demonstration and slow-motion videos, changeover walkthroughs and more. These resources help you visualize exactly how an INSITE erector fits into your line.

Floorplans

-

Floor Plan for Case Erector / Tape / Left Hand.pdf

This 1-page pdf provides you with a clear understanding of the space that our left-hand tape-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Tape / Left Hand.dwg

This .dwg file provides you with a clear understanding of the space that our left-hand tape-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Tape / Right Hand.pdf

This 1-page pdf provides you with a clear understanding of the space that our right-hand tape-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Tape / Right Hand.dwg

This .dwg file provides you with a clear understanding of the space that our right-hand tape-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Glue / Left Hand.pdf

This 1-page diagram provides you with a clear understanding of the space that our left-hand glue-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Glue / Left Hand.dwg

This .dwg file provides you with a clear understanding of the space that our left-hand glue-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Glue / Right Hand.pdf

This 1-page pdf provides you with a clear understanding of the space that our right-hand glue-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Glue / Right Hand.dwg

This .dwg file provides you with a clear understanding of the space that our right-hand glue-seal erector will occupy on your plant floor.

-

Definition: Left Hand Machine / Left Hand Case.pdf

Check out this 1-page tutorial on how to determine whether a particular packaging machine is a 'Left-Hand' machine.

-

Definition: Right Hand Machine / Right Hand Case.pdf

Check out this 1-page tutorial on how to determine whether a particular packaging machine is a 'Right-Hand' machine.

-

INSITE Warranty Statement

This 2-page document outlines INSITE's limited warranty for various aspects of its packaging equipment.

Videos

-

3D Video

Experience an overview our INSITE's Case Erector and its stand-out features.

-

Active Case Squaring

Get perfectly squared cases without stopping production. INSITE case erectors automatically detect skewed corners and use micro-adjustments to correct and ensure all corners are at 90-degree angles.

-

Changeovers in Under 5 Minutes

INSITE's case erector offers an easy-to-use recipe generation tool with tool-less changeovers. In three simple steps, you can easily set up and run new case sizes in less than five minutes.

-

Simplified Packaging with SCARA Robot Technology

Our case erector’s SCARA robot technology simplifies everything. Requiring 40-60% fewer parts than a traditional case erector, SCARA enables a leaner, quieter case erector that is easy to learn and easy to operate. Plus, it allows you to run new case sizes in just 2-5 minutes.

-

Proven & Reliable Case Opening

When a case erector first opens a case, common problems like glue overspray and incorrectly formed cases can slow down production. INSITE's case opening design uses positive case opening (opposing cups) to simplify the process and increase efficiency.

-

Software Simplifies Machine Operation

INSITE's intuitive HMI brings full case erector control right to the operator's fingertips. Access machine data, generate new recipes and operate the case erector through one simple interface — no advanced training required.

-

Built for Durability & Safety

The INSITE case erector's open frame design makes components clearly visible and easy to access. Its high durability and accessibility ensure that changeovers and maintenance are simple, safe and efficient.

-

E20G active case squaring

Look closely and you'll notice the instantaneous adjustments made by the independent side belts as the cases pass the photo eyes.

-

E20G SCARA arm movement

Watch the smooth motion path of the SCARA robotic arm operating at 20 cases per minute. There's no sound coming from the packaging machine, but even if there were you wouldn't hear much.

-

E20G at slow speed with no case

Watch INSITE's erector operating at low speeds with no cases. See the entire case erecting process through multiple cycles of 'pick,' 'rack-open,' and 'place'.

-

E20G erecting at 20 cases per minute

This quick clip demonstrates INSITE's hot-melt glue case erector operating at 20 cases per minute.

-

E20G 20 cpm dry cycle 1

Click here to view INSITE Packaging Automation's 20 cpm hot-melt glue case erector operating at full speed without cases.

-

E20G 20 cpm dry cycle 2

This is another perspective demonstrating INSITE's 20 cpm hot-melt glue case erector operating at full speed without cases.

-

E20 slow speed dry cycle end effector

See the end effector operate in slow motion on INSITE's E20G case erector.

-

INSITE E20T erector animation

This animation clearly demonstrates why INSITE's E20T tape-seal case erector is so refreshingly simple compared to alternative packaging machines.

-

INSITE E20G erector animation

This animation clearly demonstrates why INSITE's E20G glue-seal case erector is so refreshingly simple compared to alternative packaging machines.

-

INSITE E20T Fly-Around

In this wonderful animation you can see the E20T in action from all angles as it erects and tape-seals RSC cases.

Discover Other INSITE Solutions

INSITE case sealers, loaders, palletizers, and hand-pack stations are designed to integrate easily with our erectors, supporting a wide range of case sizes and line speeds. Together, they create a complete, efficient end-of-line packaging solution.

FAQ: Case Erectors

-

What is a case erector?

A case erector automatically forms, folds and seals corrugated cases from flat, or knock-down, blanks. These machines reduce manual labor and improve packing line consistency.

-

Are INSITE’s case erectors fully automatic case erectors?

Yes. All INSITE erectors are fully automatic and utilize our SCARA robot technology for smooth, repeatable motion.

-

How do I determine “machine hand”?

Stand on the operator/HMI side and observe the case travel direction.

- Right → Left = left-hand machine

- Left → Right – right-hand machine

Note: Machine hand must match case hand.

-

How do I determine “case hand”?

Note: Machine hand and case hand must match.

-

What case types do INSITE’s machines run?

Regular Slotted Cases (RSC), Half-Slotted Containers (HSC), and display trays.

-

What type of hot-melt glue does INSITE recommend?

We recommend HB Fuller Advantra PHC 9256 or Henkel Technomelt Supra 106M.

-

How do I configure a case erector, and what options are available?

Visit our Get a Quote page. It will walk you through the simple configuration process.

-

Can I buy INSITE case erectors through a local agent or distributor?

Yes, if your agent or distributor is willing to purchase and resell our case erector machines to you, they are free to do so.

-

Does INSITE Packaging Automation customize its products?

Yes—while standardized components help control cost and lead time, INSITE can develop custom solutions when needed.

-

What is the lead time for an INSITE case erector?

INSITE strives to achieve market-acceptable lead times on all product deliveries. To start, we anticipate 8- to 16-week lead times, depending on the product configuration requested.

-

What makes INSITE different?

A simplified mechanical architecture, SCARA-based movement, intuitive HMI, and a design philosophy focused on reliability and operator ease.