Which would be a wiser decision: purchasing a cheaply made set of tools that could break down mid-project, causing a panic and requiring fast replacement, or investing in a more high-quality toolset that will be your reliable companion on projects for years to come? Depending on who you ask, the answer may differ – but at INSITE, we believe our customers should never be forced to choose between quality and affordability.

When it comes to your corrugated material needs, the vast variety of prices and material options can make the choices between affordability, reliability, and quality quite confusing for companies. Although it would be simple to take the easy route and choose whatever corrugate is the most affordable, the effects of selecting the wrong corrugated material for your packaging needs could cost you far more in the long run. Take the time to examine all budget considerations, packaging aspects, and any other factors affected by your choice of corrugated cases to ensure that your company can stand confidently behind its choice.

What Is Corrugate?

Not to be confused with cardboard, which is a piece of fluted paper sandwiched between two liners made of heavy paper-pulp, corrugated material is made up of a number of layers of heavy-duty paper, which determine the wall thickness of a case. At a minimum, at least one layer is “fluted” in waves. The fluted layer is attached to at least one other layer of flat paper, called a liner. Referred to by some as containerboard, corrugated material comes in a wide variety of configurations.

Types of Corrugated Material

Although corrugated material is classified into many types, four specific options are the most commonly used in the CPG and secondary packaging industries. Differentiated according to their wall thickness (the number and combination of flutes and liners), the four most common types of corrugated case materials have various advantages according to their cost, weight, and flute dimensions. Here’s a quick breakdown of the most popular types of corrugated casing.

1. Single Face

Comprised of one piece of fluted paper glued to one sheet of liner, single face corrugated material is best suited for cushioning and puncture resistance of flat products that would otherwise be vulnerable to damage during transport.

2. Single Wall

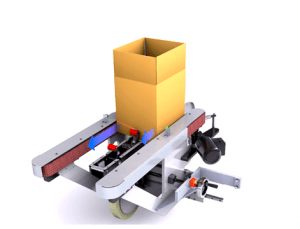

Consisting of one piece of fluted paper glued between two liner sheets, single wall material – like the cases INSITE utilizes in our case erector and case sealer machines – is ideal for lightweight products that need some protection during distribution.

3. Double Wall

Built from two pieces of fluted paper glued alternatively between three liner sheets (in the format of sheet/flute/sheet/flute/sheet), double wall corrugated material is well suited for transporting heavier items. The alternate layers strengthen the resulting cases immensely, allowing them to withstand stacking.

4. Triple Wall

The big brother of double wall corrugated material, triple wall packaging is comprised of three pieces of fluted paper glued between four liner sheets, again in an alternating pattern. The densest of the most common corrugated materials, triple wall material is best used for transportation of heavy-duty items and insulation.

Corrugate Cost Isn’t Just About (Upfront) Money

All of the above types of corrugated packaging have different costs, with additional layers increasing the final weight and price tag of your packaging. Because these costs affect your budget accordingly, it can be easy to let financial factors weigh heavily on the decision of which corrugated material offers the best solution for your packaging needs. However, the financial factor in this decision extends beyond the immediate cost. Just like a person who purchases a cheap tool kit will be forced to purchase another kit later after the first falls apart, “saving” your budget by going with a less expensive corrugated material won’t really save it all – because the cheapest packaging material isn’t necessarily the cheapest option in the long run.

If your products benefit most from a triple wall corrugated case, opting for a single or double wall corrugated material for the sake of saving money is not doing your product (or your customers) any service. Cutting costs is important to maintaining your bottom line, but saving money at the expense of your product’s integrity is not worth the price. And if you choose the wrong casing material, that price could be damaged or lost inventory, a slow packaging process, and lost profits.

We buy the better toolkit to make sure that no matter what unexpected projects pop up, we are equipped to handle them. In the same way, choosing a corrugated material you can have confidence in is the best choice for your secondary packaging process.

Package Better with INSITE

No matter which corrugated casing material best fits your packaging needs, INSITE is eager to support your efforts through thoughtful machine design, quality customer service, and unbeatable advice. Start simplifying your packaging process today – we’ll get you set up with the right equipment to erect and seal cases beautifully and efficiently.