Lasting, Effortless Efficiency.

Case Loaders

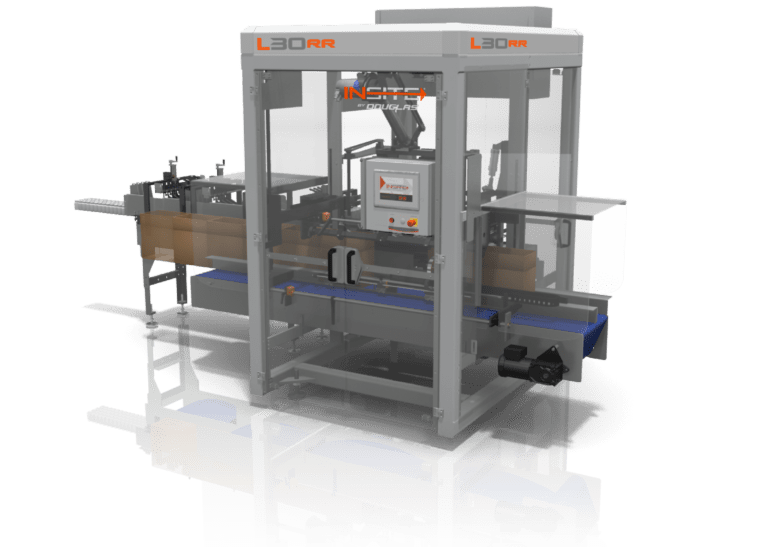

Upgrade your packaging line with INSITE’s new case loader – where efficiency, simplicity and durability align. INSITE’s technology offers next-level funtionality in straightforward, clean and easy to operate machines.

The new INSITE Case Loader designed to bring unmatched simplicity and productivity to your can, jar or plastic bottle packaging. Our automatic case loaders pack products into pre-formed, top-load cases quickly and effectively. Seamlessly integrate INSITE’s case loader with your existing erector or sealer, or begin your investment in automation with a standalone INSITE case loader.

Key Features

INSITE’s case loader is primed to help you simplify loading for your vitamin, supplement, canned food, sauce, condiment, beverage, cosmetic, personal care product - or any other round, rigid product - with the cleanest, simplest most robust case loader on the market. Delivering on reliability and easy of use, here are the top features that make INSITE’s case loader stand out:

Compact and accessible design

With its small footprint, the INSITE case loader fits seamlessly into your production environment while offering easy access for operators.

SCARA-enabled simplicity

Experience the elegance of INSITE's trusted SCARA motion that results in over 40% fewer parts. This means less maintenance, minimized downtime, and smoother operation for you.

Parameterized setup

Enjoy quick, hassle-free startups and changeovers thanks to our parameterized setup. Your team can easily adapt to changing production demands with minimal headaches or training.

Quality you can count on

Built with the enduring quality you've come to expect from INSITE and Douglas, this case loader is designed - and built - to last.

Case Loader Capabilities

Below, you’ll see a list of facts and figures about INSITE Packaging Automation’s case loaders. If you need additional information, please contact us. We’ll provide all the resources you need to choose the machine that works for you.

| L30RR | |

|---|---|

| Case Type | RSC (regular slotted containers) and HSC (half slotted containers) |

| Min. Case Size | 7" (L) x 4.5" (W) x 4.25" (H) |

| Max. Case Size | 22" (L) x 16" (W) x 16" (H) |

| Min. Container Size | 1" outside diameter, 1.5" vertical |

| Max. Container Size | 7" outside diameter, 12.5" vertical |

| Speeds* | *Up to 30 cases per minute depending on pack patterns 15 picks/minute at 20kg (product + end-of-arm tooling) 10 picks/minute at 30kg (product + end-of-arm tooling) |

| Min. Pack Pattern | 1 unit depth (direction of travel), 1 unit facing (across machine), 1 unit high (layers) |

| Max. Pack Pattern | 8 units depth (direction of travel), 6 units facing (across machine), 6 units high (layers) |

Case Loader Innovations

INSITE Packaging Automation is commited to enhancing your packaging processes through automated solutions that work around your budget, while maintaining

our high standards for quality. Our case loader offers maximum functionality in a compact package, using our proven advanced technologies to expand automation

offerings for your business. See how INSITE’s case loader can transform your production line:

Accurate, efficient product handling

Ensure consistent product handling and placement with simple infeed options, product load funnels and positive case positioning. INSITE’s innovative technologies streamline the packing process and minimize errors.

Reduced maintenance

Reduced lubrication requirements mean less maintenance and lower operating costs. In addition, the Full Guard Door Package provides comprehensive protection while maintaining easy access for maintenance. With INSITE, maintenance doesn’t need to be a headache.

Simple operation and safety

INSITE’s case loader is designed for easy, safe operation. The intuitive Human-Machine Interface (HMI) makes it simple for operators to monitor and control the machine with minimal training. Every loader is equipped with advanced safety measures to ensure operator protection and meet industry standards.